RO-EDI Technology

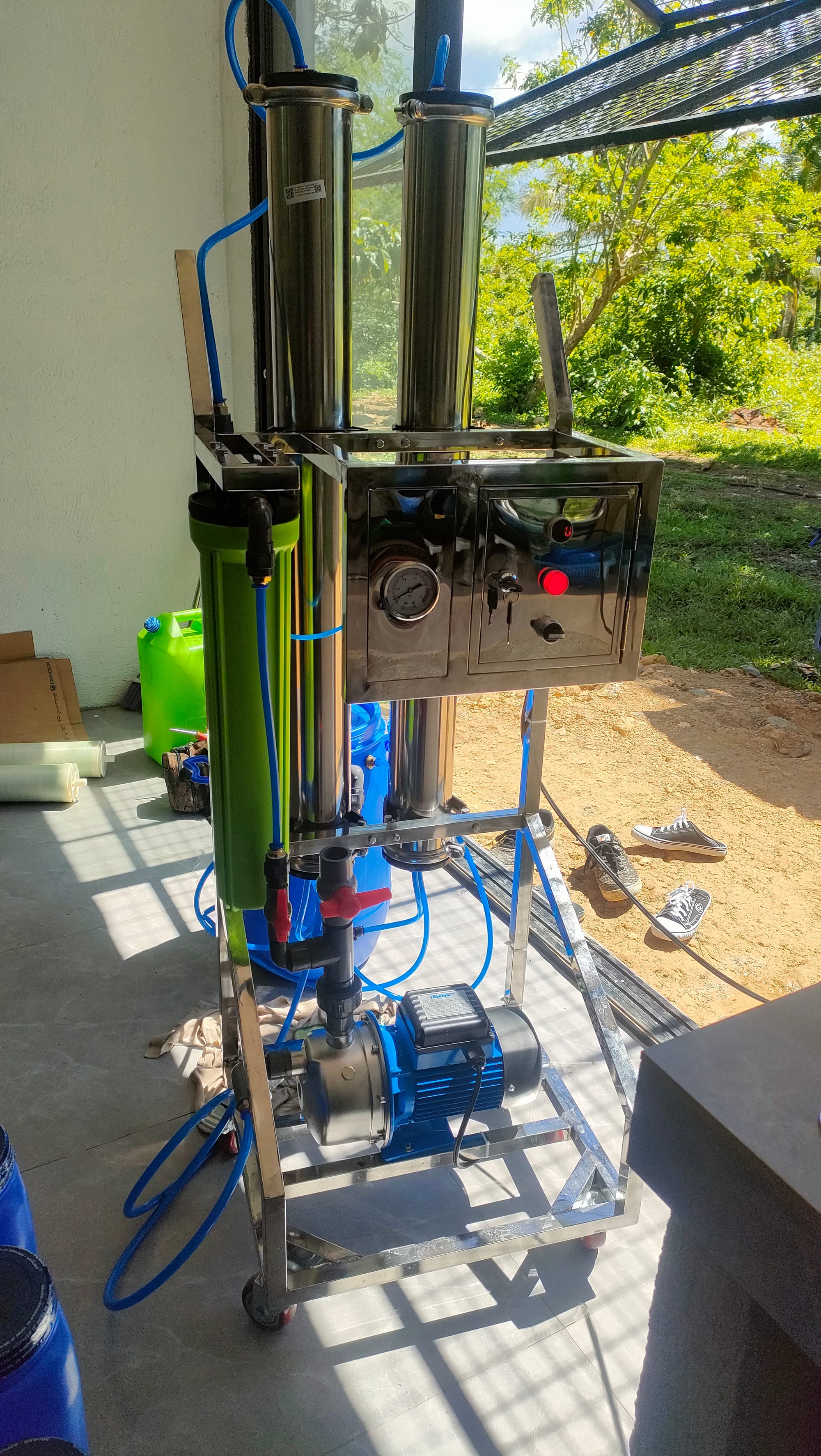

Reverse osmosis electro deionization, or RO-EDI, is the most popular water filtration method, mostly used in food and pharmaceutical sector. Both the techniques of reverse osmosis and electro deionization are essentially combined in RO-EDI systems.

What is RO-EDI (Electro deionization) water treatment system?

A RO-EDI system uses single or double pass RO to pre-treat feed water before sending it on to electro deionization, which produces the highly pure water of 10-15 M needed for sensitive applications. It is also used to treat the boiler water in power plants.

What are the benefits & features of RO-EDI water treatment systems?

The product water output = 20000 LPH They produce high purity water of 10 - 18 Mega Ohms?

Panel mounted resistivity meter with digital indication is installed The VFD-driven pumps for precise control of all unit operations are present

It reduced hazardous waste stream The overall recovery is 100% (approx.)

There is automatic sanitization, backwash, rinse, & recycle functions It is completely skid mounted including pretreatment options

It can be customized for specific customer requirements It has manual & automatic reverse osmosis system

What are the typical applications of RO-EDI systems?

Pharmaceutical

Used in Power Industry

Laboratory Water

Food processing industries

Production of Highly Purified Water

Rinsing of Electronic Components

Used for Glassware Rinsing Cosmetics

For Preparation of Process Chemicals

Benefits of 2-pass RO Systems for RO-EDI water treatment systems

The following benefits are provided by two pass RO, which is frequently utilized in power plants or pharmaceutical applications.

· Higher EDI quality

· Higher silica removal due to lower CO2 results in less frequent EDI cleaning

· Rated fluxes for EDI that are higher

· For greater EDI performance, a single pass RO system can be improved with a membrane degasser

· Membrane degassers can lower CO2, which improves EDI performance, lowers the risk of scaling, and aids in the removal of SiO2 by the EDI machine.

EDI water treatment systems can be provided with a wide range of

options:

· RO is followed by EDI modules, then softeners.

· Softener, RO, membrane degasser, and EDI modules.

· RO is followed by caustic dosing, RO, EDI modules, and final caustic dosing.

Without pH adjustment or membrane degasser, it is difficult to achieve the feed specifications for the EDI water treatment plants. The product quality will increase by reducing CO2 before the electro deionization system, which will result in a reduced load (lower amps).

Water treatment systems from Roditek.

Better water is produced by Roditek Fluids RO-EDI water treatment systems, which are designed, built, and installed with safety and the environment in mind. These machines may generate between 10-19 Mega Ohms of pure water outputs, depending on the feed water quality and flow rates. Our RO-EDI Plant units can be constructed as manual or fully automatic kinds equipped with PLC systems, according to the needs of the customer.

Our quality management system has been certified, and we encourage our clients to talk to us about the high-quality, pure water they need for their specific applications.

Our technical staff is able to precisely design and build the device, which satisfies beyond client quality criteria. Call us at +63 920 54987043 or email at info@rodi-tek.com for further information.

+63-9205498704 - Installation

+63-9205498704 - Installation